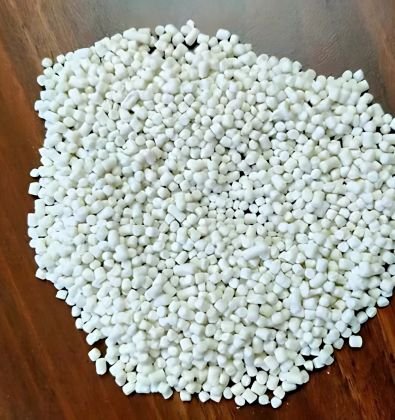

CaCO₃ Filler Masterbatch

Calcium Carbonate (CaCO₃) Filler Masterbatch is one of the most widely used and cost-effective plastic additives in the industry. Known for its exceptional whiteness, high thermal stability, and ability to reduce polymer consumption, CaCO₃ filler is essential in applications where strength, opacity, and surface finish are critical.

At Asian Tradelinks, we import and supply premium-quality CaCO₃ Filler Masterbatch tailored to diverse processing needs. Renowned for their consistent quality and high loading capacity, our filler masterbatches help customers maximise material efficiency while maintaining product strength and aesthetic appeal. Our grades span across PE, PP, and HDPE bases and are manufactured with high-purity CaCO₃ powder, ranging from 75% to 85% concentration. These masterbatches are compatible with most thermoplastics and enhance mechanical performance while improving printability and extrusion speed.

- Reduces overall raw material costs by replacing a portion of virgin polymer

- Enhances whiteness and gives products a glossy, clean finish

- Increases dimensional stability and stiffness in the end product

- Improves thermal stability during high-speed extrusion

- Compatible with multiple polymer bases (PE/PP/HDPE)

Advantages of Our CaCO₃ Filler Masterbatches:

- LDPE and HDPE Tarpaulins

- PP Woven and Non-Woven Sacks

- Carry Bags and Garbage Liners

- Injection Moulded Furniture and Household Goods

- Thermoforming and Blown Film Applications

We offer customized solutions for a wide variety of industries, including:

- CaCO₃ Content: 75% – 85%

- Recommended Dosage: 40% – 80%

- Carrier Resins: PE / PP / HDPE

- Appearance: White Granules

- MFI Range: Tailored to customer requirement based on application

- Particle size of Caco3 powder: Fine-grade CaCO₃ for optimal dispersion

Technical Specifications:

Below is a breakdown of the key polymer-based applications: Our Filler masterbatches are available in PE, PP, and HDPE bases, each tailored for specific applications. These fillers are known for their excellent whiteness, which imparts a smooth, shiny finish to end products, while also enhancing stiffness, thermal stability, and processing performance.